| Home | For sale | Site map | Contact information | Guest book | Lafette-menu |

The

Lafette accessories The

Lafette accessories  |

|---|

A limited selection!The

Lafette 34 & 42 only came with two different accessories;

the anti-aircraft extension tube with swiveling gun mount and the

leather carrying straps. The optical sight was not a part of the

Lafette and was considered a separate supply item. That item will be

covered in a separate article.

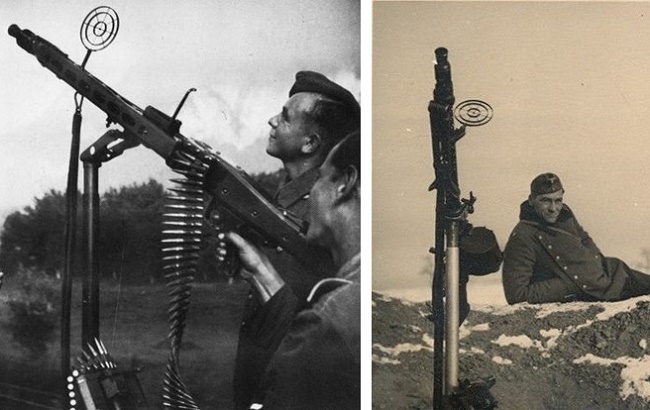

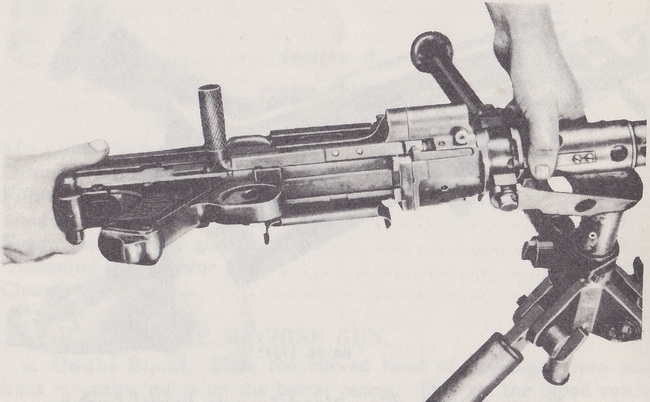

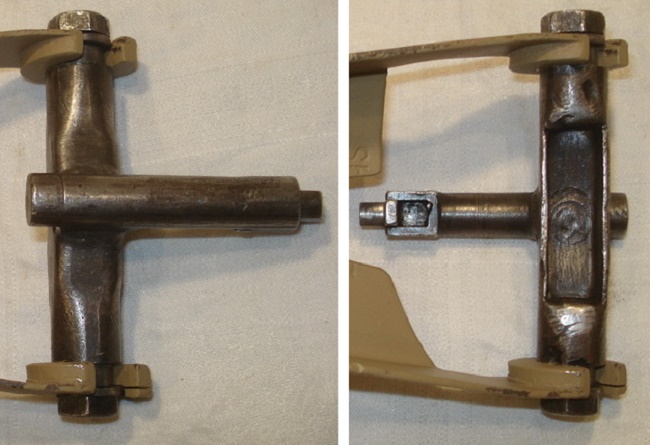

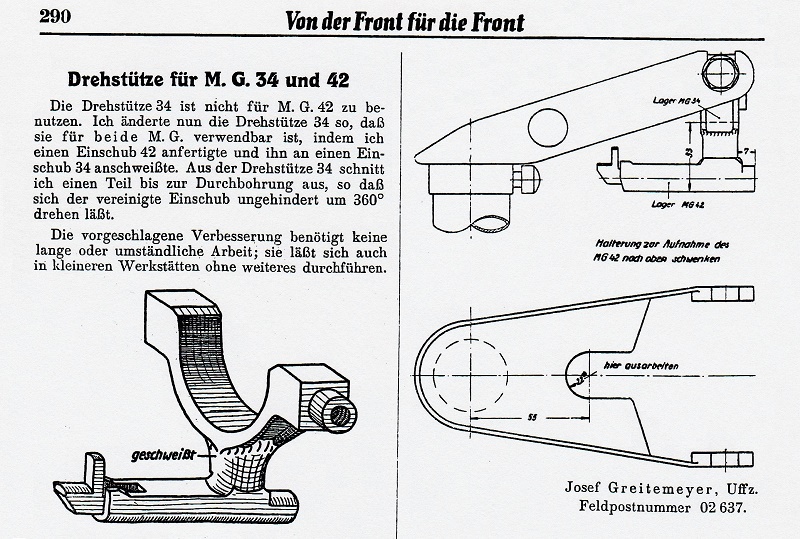

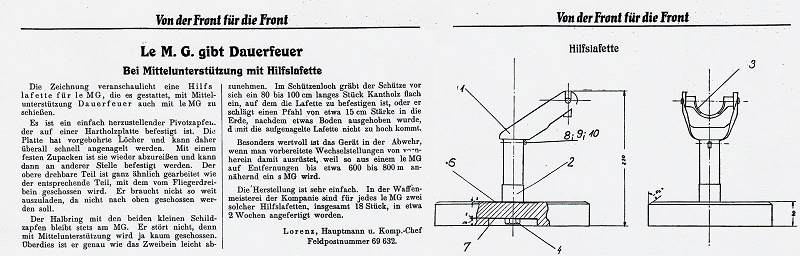

The manual "D 124/2 Maschinengewehr 34, Teil 2, MG Lafette 34" lists both items as parts of the Lafette. From all accumulated information I believe that all Lafettes came with the carrying straps, while the anti-aircraft extension tube with gun mount was issued on a more limited scale. I will discuss these two items in separate sections, beginning with the carrying straps. All of these items come in three varieties. -The original, factory manufactured item. Marked with a maker's mark/WaA/date, almost always. -A Waffenmeister made item. Handmade by the armorer as a replacement part during the war, as enough factory made items couldn't be sourced. Never marked like the above. -A postwar item. Either a surplus item, manufactured and used by a postwar army, or a pure copy, made to deceit a collector or to just be a place-filler in a collection. Any markings resembling the above would be fake. Part 1

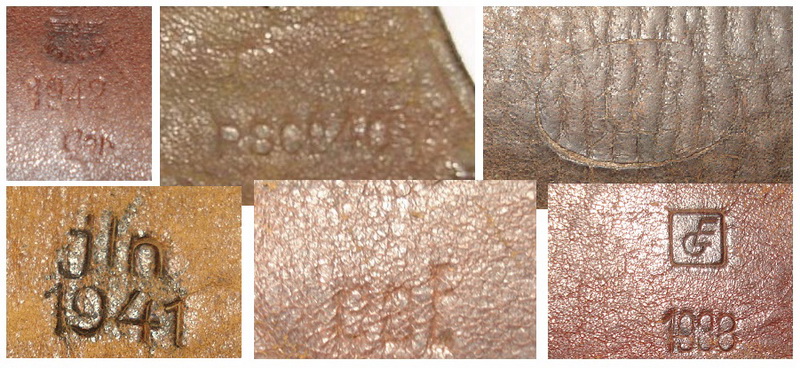

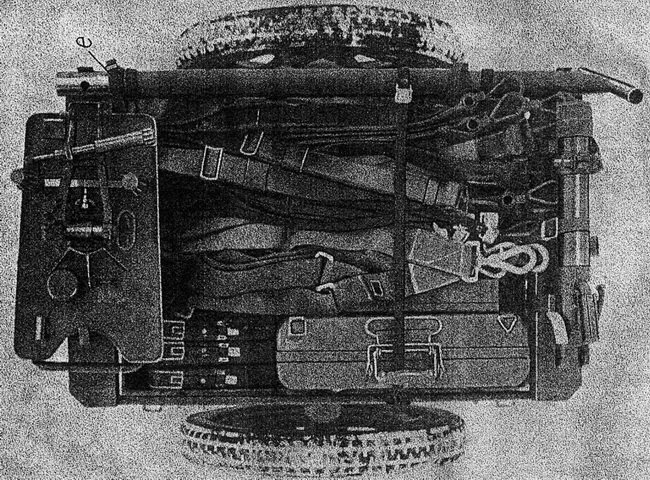

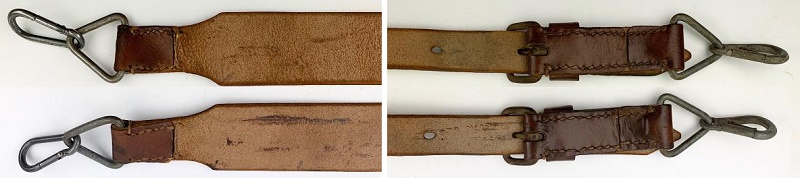

Trageriemen The carrying straps came as a pair, and were attached to the four D-rings on the lower Lafette.  Combined with the adjustable leather pads on the front leg of the Lafette the straps made it possible to carry the Lafette as a rucksack. A rather heavy one... weighing in at 23 kg / 50 lbs. The carrying straps N are used to carry the mount on the shooter's back. They are hooked to the rings on the frame. The carrying strap consists of the shoulder strap with snap hook and the buckle holder with roller buckle, ring and snap hook. The above picture displays the evolution line of the Lafette carrying straps.....there isn't any. Apart from one small simplification to the snap hooks in 1944, all Lafette carrying straps were manufactured the same way, with the same parts. From bottom up they are matching, dated 1940, 1941, 1942 and 1944. But inspected examples dated 1937, 1938, 1939 and 1943 are all the same. A 1945 dated set has not been observed so far. So to keep it simple; there is no alternative shape. Any Lafette strap that doesn't look like the above is not an original factory manufactured item. (Period / Full stop.) The buckles Each end has a triangular "ring" with a permanently attached snap hook. The leather is simply folded over the triangle and sewn down with 2 or 3 rows of stitches. The triangular shape distributes the weight of the Lafette (23 kg) from a single point of contact to the broad, thick leather straps, easing the burden on the marching soldier. The standard variety of the snap hook, as used from 1936 to 1944. The simplified model was introduced in 1944. The snap hook spring was now moved inside the locking arm, and the snap hook was simplified in its construction. These hooks have never been observed with markings. The standard model of the snap hook w/ triangle "ring" has been observed without marking, marked with "R244 (unknown), marked L&F for Linden & Funke G.m.b.H or S/fir tree/C for Schmöle und Co. Menden. The leather The straps were manufactured in brown leather. No other color has been observed, but the brown will turn very dark, bordering on black, with heavy use. They have a distinctive shape, with a wider section for the user's shoulders. All observed examples have four adjustment holes for the roller buckle. The leather on the long (upper) strap measures approximately 61 cm, or 24 inches on this specimen, but the length could vary between 60 and 64 cm. The leather on the short (lower) strap measures approximately 11 cm, or 4.33 inches. As usual on German leather the edges have been lined with impressed, darker lines.  Markings and makers The slings will always be marked in the same spot; the upper part of the wider section, on the smooth "outside". The marking has three components; The WaA approval eagle, a manufacturer's marking and the year of production. In addition, the slings manufactured pre 1940 will most of the time have the same markings on the short (lower) strap. Sadly, on most slings this marking will be so worn that it is impossible to read. Some makers marked their slings with faint stampings, and wear and tear will have removed the rest. Of special interest in the picture above is the last strap, manufactured by the Lafette maker fsu (Brandenburger Fahrrad und Motorradwerk, Excelsior). They changed to the new year-coding system on their Lafettes in 1944, and this was also used on the carrying straps. "NC" denoting 1944/fsu. The strap above dated 1940 has the "S above 968 inside a triangle"-marking, the same that was used on the Lafettes manufactured by btm (Hülsbeck & Fürst, Schlossfabrik).  Some of the surviving slings were made by the same manufacturer that made the actual Lafette, while other slings have been made by other leather manufacturing companies. fsu was the Lafette maker that made most of the slings, but specimens from dar, btm and eat has also been observed. I have never seen slings marked SWITZ or ecy, but they might exist. A complete mapping of the sling makers is not within the scope of this article. The one in the upper right corner is marked "Albin Scholle, 1940, Zeitz". The one in center reads "RSCo40". The lower right is a factory logo "GE" or "EG", and only observed on (plenty of) pre-1939 dated slings. Markings on early short (lower) part of the Lafette carrying sling. Anomalies A standard sling is fine, as long as it lasts, or as long as the supply system can keep up with losses. When the demands can't be met, the soldiers will improvise and the Waffenmeisters will find a remedy! The

lower sling is 1938 dated. At one point in its service career the

standard snap hook has given up the ghost, and has been replaced with a

hand-forged triangle "ring" and a larger non-standard snap hook. The

parts were painted in Dunkelgelb to prevent them from rusting. Some of

the paintwork is still visible underneath the Norwegian army Olive

Drab, applied postwar.

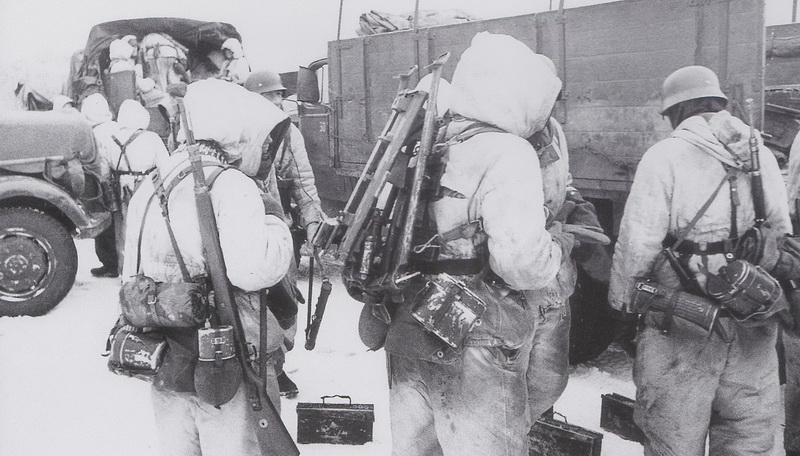

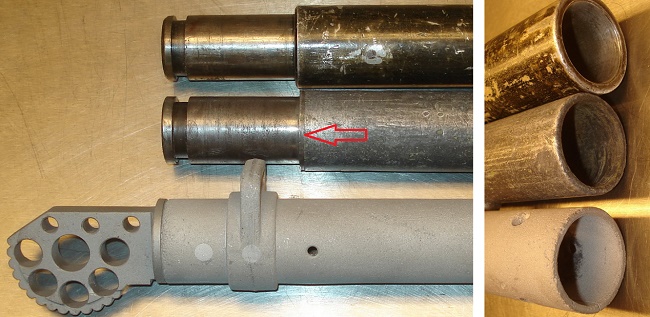

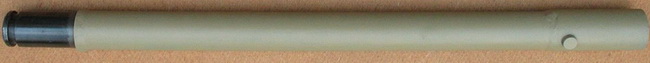

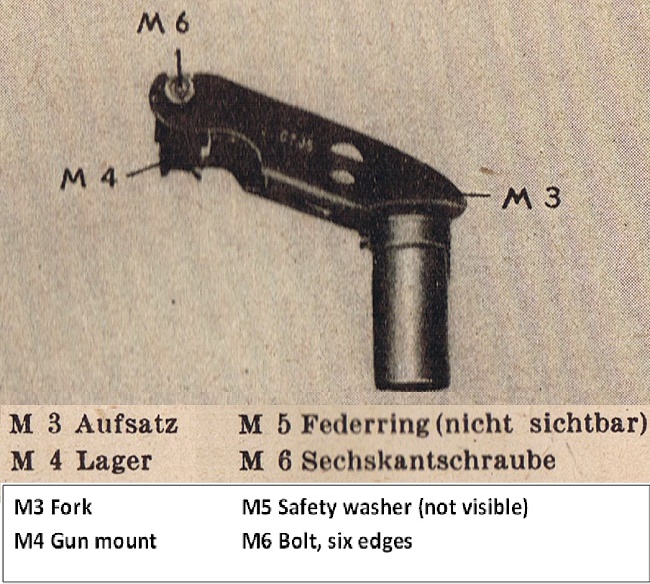

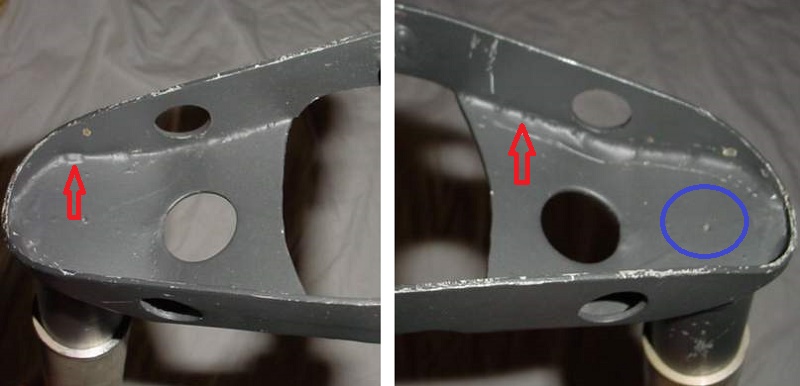

(Pictures courtesy of Folke Myrvang) The upper sling above still has the original hardware, but the leather has been replaced. The lower sling has only got the upper snap hook / triangle "ring" intact. All the rest has been repaired/reconstructed by the Waffenmeister. And when no one else can help you, help yourself! In the words of Gunny Highway; Improvise, adapt, overcome.  The Lafette 42 above is using a Tragegurt 34 instead of the Lafette Trageriemen. The Tragegurt 34 compared with the Lafette Trageriemen.  Photo by SS-PK Ernst Baumann The MG crew above has used a pair of the heavier pull-straps as a substitute for the Lafette Trageriemen. These slings were normally issued to assist in pulling heavy equipment in position. They can be told apart from the Tragegurt 34 by the tube that the strap has been sewn around, just visible on the photo above.  This picture from the IF8 manual shows the pull straps (upper right corner) as issued when used with the IF8 trailer loaded with mortar equipment.  Anything goes! Russia, summer of 41. This Lafette has been set up with a pair of Y-straps as a improvised method of carrying the Lafette.  The original straps in use, with the Lafette carried as a rucksack. Postwar slings Oh yeah. The Lafette saw continued use post WW2 with several armies, as covered in my article Postwar era. But no army copied the WW2 German design of the slings, so there is no reason to run ashore mistaking a pair of surplus slings for the real deal. As I stated above; there was only one design of the slings, and unless they look like the ones in my article they just ain't original German WW2 slings.... Modern, good copies are also somewhat scarce, as the special set up for the buckles with the triangular "ring" is not a standard hardware readily available for the fakers.  This is an example of a pair of fake slings, recently offered up for sale. The faker has obviously got hold of the hardware from one damaged sling, and has made a pair out of it, by using the original snap hooks at the bottom sections. The top ones, although they appear similar to the 1944 model snap hooks, are made of bright stainless steel and are thinner and larger than the 1944 ones, and not permanently attached to the triangle "rings" as they should be. These slings also have a set of bad markings, wrong leather, wrong finish and bad cutting of the leather. For reenactment use, the company ATF makes good copies, all supposed to be marked jsd 1944. Although very well made, they can be told apart from the real deal by the snap hooks. Part 2 Lafettenaufsatzstück The mount attachment piece (Lafettenaufsatzstück) is used to shoot the MG34 from the Lafette in the standing position against air targets or against ground targets (over hedges, grain fields, etc.). It consists of the support tube and the gun mount. The support is a tube and it is pushed with its lower end onto the pivot pin of the MG mount. It is held in place by a catch under coil spring pressure. On its upper end there is a pivot pin identical to the one on the Lafette. The attachment (Aufsatz) is put with its sleeve on the pivot pin of the support and also held by a catch. An arm is welded onto the sleeve, at the end of which the bearing with spring washer and screws is rotatable inserted in reinforcements open at the top. The bearing has front and rear strips for inserting the central support of the MG. Tilt compensation is made possible by recesses between the strips.  The Aufsatzstück could be used against both air targets and ground targets. It consisted of two main parts; the Stütze and the Aufsatz. The Stütze was simply an extension pole that raised the gun in height. The Aufsatz was the actual gun mount, with one out of two different "Lager". The Aufsatz could be set up for the MG34 or the MG42.  The Lafettenaufsatzstück is seldom seen in pictures unless it is in use. The picture above shows it lying beside a Lafette 42. For a full view and description of this picture from February 1945, go to the very bottom of the Lafette 42 page. Of special interest: this Lafette was made by "dar" in late 1944 / early 1945, but the Lafettenaufsatzstück had not been in production for over a year by the time this Lafette was manufactured. Odd to see them together in a late war picture like this.  A German SMG team is digging in at a road junction in the Soviet Union during Operation Barbarossa 1941. The MG is in use as a LMG in the background to provide security until the team has managed to dig in and set up the Lafette.  A close-up of the equipment pile. A double barrel carrier, the Laufbehälter 34, with "7" painted in white at the bottom. The ammunition cans have been carried with the aid of the load-bearing strap, the Tragegurt 34. But the most interesting detail here is the Lafettenaufsatzstück. It has been attached to the Lafette by using the forward gun mount lever clamp. This method of carrying is not described in any of the manuals concerning the MG34 or the Lafette. In fact, the method of transporting the Lafettenaufsatzstück is not mentioned anywhere that I can find. The two individual parts of the Aufsatzstück is best analyzed one-by-one, so here goes! Die Stütze The extension tube was made from Düralumin, the same material that was used for a lot of the smaller parts on the Lafette, like the buffer and the mounting base for the optical sight. And just like those parts, the Stütze came in two different colors; brown or green, depending on manufacturer and year of production. The Stütze was made and used solely with the Lafette. It was not issued for any other purpose. But it was used with one other set-up that I know of.  The Waffenmeister designed and produced Fliegeraufsatzstück für IF8. The Lafette to which the Lafettenaufsatzstück belongs is just visible on the cart to the left. The above photo shows the variations in the production from the early (bottom) to the latest (top)..... again absolutely no difference. The factory manufactured Stütze are all identical, apart from the markings and color. The main tube is always made from Düralumin, with the details made from steel. The pivot pin is fitted inside the hollow main tube and riveted in place with two rivets. A spring pressured catch is installed at the bottom end with one rivet. The marking is always applied at the top end of the main tube. Up until now, no "all-steel" version with legit markings have been found, so Stützen made of steel are either Waffenmeister made, or postwar made. (I have seen pictures of an all-steel Stütze marked "ecy", but the pictorial evidence was not good enough to draw any conclusion. If they do exist, they are very rare for sure.)  The green variety of the Stütze, the marking on the tube is visible at the top end (at the left). This one made by fsu. The brown variety of the Stütze, this one made by btm. This item was repainted in Dunkelgelb during its lifespan.  The quality of the anodizing on Düralumin was "variable" to say the least. Some items appear like new, even up to this date, while others must have lost the color at once. Just glance at the comparison picture of the four tubes above. Markings and makers The composition of the markings would vary according to the maker.  Brandenburger Fahrrad und Motorradwerk, Excelsior (S323/fsu), offered the full monty! Maker's code, year of production, WaA approval and serial number. All markings initially filled with white paint from the manufacturer.  Hülsbeck & Fürst, Schlossfabrik (S968/btm). Maker's code and WaA approval. Early marking also included a serial number. All markings filled with white paint from the manufacturer. Metallindustrie Schönebeck A.G. (S652 / dar) Maker's code and WaA approval.  Fouquet & Franz AG, Rottenburg Neckar (ecy). Maker's code and WaA approval. All of the Stütze I have seen were manufactured by one of the registered Lafette makers, but I haven't seen a Stütze from all of them yet. fsu appears to be the only manufacturer that marked them with the year of production. All of them have the WaA approval stamp. The serial number is a bit of a mystery though. The S968 (btm) Stütze above is marked with the serial number 8209. But they never manufactured a Lafette with this serial number, they had a "b" or "c" suffix on all their Lafettes until the production of the Stütze was stopped, so it has nothing to do with the serial number on any of the Lafettes manufactured by this maker. If we move on to the S323/fsu Stützen pictured above a even more complicated picture emerge. The first one is dated 1937, serial number 1087. But the Lafettes had no serial number in 1937. The numbering sequence was started in 1938. I believe "1087" was applied post-factory. The next one is dated 1941 and has serial number 8084d. This serial number is actually corresponding with Lafette production in 1941 and could well be matching a fsu 1941 manufactured Lafette. The next one is 1942 dated with serial number 9826d. This combination is also a possible match, but Lafette serial number 9822d is 1941 dated, and no Lafettes in the "d" series has been found dated 1942 until now. The last one is dated 1942 with the serial number 5735g. This is absolutely not a Lafette serial number. The serial numbers in 1942 go up to about 5000, with no letter. In 1943 they manufacture in the "a" series. No Lafettes have been observed with a "g" serial number. To top it off, the second "possible" serial number comes with a matching numbered Aufsatz. Picture courtesy of Tom Ødemark Keep in mind that the Stütze was only manufactured for, and used with, the Lafette. So a serial number on one of these would either be an inventory number, or connected with the serial number of the Lafette it was issued with. From the five serial numbers studied here, only two could have been matching a Lafette serial number. Until further examples can be studied I leave the conclusion on the serial number in limbo.... Anomalies As with the straps, supply and demand didn't always match. In addition, the extension pole for the Lafette was deemed "unnecessary". Production was discontinued in 1943. This initiated "improvised production" by the units. Several versions of Waffenmeister made Stützen exist, but they are never made of Düralumin, as that material couldn't be sourced. Picture courtesy of Folke Myrvang The above Stützen was also featured in Folke Myrvang's classical work "Mg 34 - Mg 42. German universal machineguns." This piece was made from a piece of steel tubing. The finished product was painted in Dunkelgelb, which now peeps out from a secondary layer of ordnance green. The top was turned out of the tube itself, while the collar appears to be made from welds. The "female" end was made by welding on a piece of a larger tube and adding a coil spring pressured catch. The top Stütze above was made by Hülsbeck & Fürst, Schlossfabrik (btm) and retains most of its dark brown color. It has at one stage been repainted Dunkelgelb, but less than 10% of the paint remains. The lower Stütze is a handmade item, the work of a Waffenmeister, made from Elektron tubing. Elektron was an alloy of 90% Magnesium and 9% Aluminum, and was used among other things to manufacture the Dreibein 34. I suspect the lower Stütze above was made from one of the legs from a broken Dreibein 34. The size is identical, and getting hold of Elektron tubing not already manufactured into a product would be next to impossible.  The above picture show the two Stützen compared to a leg from a Dreibein 34. The leg has been sandblasted, so the external appearance will not match, but the dimensions do. And due to the length of the Dreibein leg it could be used to make a full length Stütze (with no extra holes). As Elektron is much weaker and more fragile than Düralumin, the pivot pin has a collar that is the same size as the tube (red arrow above), which will distribute the weight and shock much better during shooting. Postwar manufactured extension poles Those countries that continued to use the Lafette after WW2 based their anti-aircraft capability on other mounts / solutions. However, the only postwar Lafette manufacturer also manufactured the extension poles.    The Yugoslavian M53 Lafette came with a copy of the Lafettenaufsatzstück. The Yugo tube was made from steel and had no markings. The construction is identical to the Waffenmeister piece shown above (with original paint), but the size difference between the main tube and the outer (lower) tube is larger on the Waffenmeister piece. The welding on the lower tube on the Yugo Stütze varies from "not visible" to "very rough". Norway made a small run of the extension tube (year and quantity unknown) as replacements for their stock of the originals. These tubes were made of pure aluminum, and had a "sandblasted" exterior. The pivot pin was bright steel and riveted inside the end.  The bottom had a black plastic liner. Note that the pivot pin has been made just like the Elektron Stütze, oversized to distribute the weight and shock evenly. The serial number was added post-factory. Der Aufsatz The adapter / gun mount that locked on to the top of the Stütze was called an "Aufsatz". This item saw widespread use with both the MG34 and MG42. It was issued for use with several types of gun mounts, mostly for AA (Anti-Aircraft) use, but also on a wide array of vehicle mountings. It consisted of several parts, as listed below.  The translation of the names of the individual parts, as well as the complete unit, could never be an exact science. These are my own definitions. This picture above shows the parts all laid out. There are two washers here not listed above, so they are most likely regarded as a part of the Lager (M4). The spring pressured catch was riveted on to the fork, so it was not counted as a separate part, but rather as a integral part of the fork. The Aufsatz would function with both models of machineguns, but the part M4 would need to be for the specific type of gun (Lager 34 or Lager 42). I will first delve on the fork itself, and then discuss the specific Lager at the end. The evolution of the fork.....almost none! There is one last version (not in my collection) of the fork manufactured with no holes to the side-walls. From the start of production until the end, the basic design didn't change at all. There are some differences in details, like the button for the catch which is twice as big on a mid-war example compared with a prewar example. But most of all the differences are results of the different manufacturer's specifications. The paintwork follows the standard "color of the year" system, see the article on Lafette paintwork for more details.  A fork manufactured by Brandenburger Fahrrad und Motorradwerk, Excelsior (S323/fsu) in 1937. It has the original 3-color Buntfarbenanstrich camouflage pattern, but due to the small size of the item, only Grün (RAL 28) and Erdgelb (RAL 17) were used, leaving no space for the third component, Braun (RAL 18). The fork was assembled from several components.  The above picture has been manipulated to show how the fork part was shaped prior to assembly. The main component was the actual fork piece, which was a (rather) complicated stamping which was shaped in two directions. At the front a large hole was punched downwards, creating a socket that would accept the tube for the pivot pin. The sides and front were shaped upwards and three holes were stamped out to make it lighter. I have not discovered any specific use for these holes.  To better support the Lager (gun mount) a half-moon disc with a slightly smaller opening was soldered on the inside of both arms. This created a recess that would hold the washer, locking the Lager to the fork while enabling it to rotate freely. On later examples the half-moons were spot-welded in place. The closed-end tube was inserted from the bottom and welded to the fork from the top. In the above picture a 1937 fork with a very nice weld, made by "S323/fsu". The right one is a mid-war example made by "dar". The welding doesn't quite hold the same standard as the prewar example. Early small versus late large button on the catch. Note the additional spot-welding on the late example to help secure the tube inside the shaped socket on the fork.  The fork arms have a slightly different design on the left and right side of the Aufsatz. The right arm has a cut-out to allow maximum elevation for the MG34, which isn't "symmetrical" in this area. For the same reason the bottom plate has been cut in an irregular shape, extending further back on the left side. The Aufsatz manufactured for the MG42 kept these profiles, so all Aufsatz' could be used for both weapons, even though the special profile wasn't needed for the MG42. I have found no "use" for the 3 holes, one to each side and one in the bottom plate. I believe they were simply stamped out to lighten the fork. This ended in a problem though. On late examples the strip of metal between the top edge and the hole was made too thin, ending in breakage during use. The example above has been repaired with a weld. This problem was remedied by the maker Metallindustrie Schönebeck A.G. (S652 / dar) towards the end of their production.  (Picture courtesy of Ed Marino) Late war Aufsatz with no holes to the sides at all can be found with "dar" markings (sadly no example in my collection.....). The actual gun mount, the Lager, was initially made for the MG34, but would also accept the MG13. It was cast, and machined where needed, leaving a rough texture on the outside of the semi-circle. This specimen has some part numbers from the casting, which is rather unusual. In the beginning it was simply called a "Lager". From the introduction of the MG42 it was renamed to "Lager 34", as it was important to distinguish between the different gun mounts.  A picture from the US TM E9-206A shows the correct mounting of a MG34 in the Lager (this specimen attached to a Dreibein 34). (Click on the picture for a full-size view) With the introduction of the MG42 the Lager 42 was "a part of the deal". The above document from 16 July 1943 mentions the future distribution of Dreibein 34, without Lager 34, but with Lager 42. The Lafette 42 with Lafettenaufsatzstück is not mentioned though..... The Lager 42 and the Lager 34 in comparison.  The Lager 42 was, of course, made to accept the MG42.  The Lager 42 was simplified towards the end of production. The new version (Lager 42 n/A) was made from welded pressings that required less machining time. Markings First of all, I will concentrate on the main part, the fork.  The maker's mark or code was normally positioned on the right side of the fork. All the above maker's codes also have a WaA mark with it. All the above makers made Lafettes. Again Brandenburger Fahrrad und Motorradwerk, Excelsior (S323/fsu) is the only maker that displays the year of manufacture, but their later forks were not dated. The serial numbers are most likely identical with the serial number of the Lafette they were issued with. With some exceptions. The btm 11435 is outside of the serial number sequence that was used on their Lafettes. The fsu "1061" is not matching any Lafette, as the 1937 production run had no numbers. Due to the irregular application of the numbers I think this was a Waffenmeister modification, like the crossed out eat 662.  The only exception to the "maker's marking on the right side" was the manufacturer Georg Appel. He applied his prewar factory logo, with the letter G inside an A inside an apple, on the top of the bottom plate. When he changed to his code "64" this was applied on the left side of the socket. I haven't observed his wartime code "cnx" on any forks yet. Georg Appel never manufactured any Lafettes, but he did manufacture most (if not all) of the Dreibein 34's. I would suggest that any Aufsatzstück made by this company was issued for the Dreibein 34 or other types of mounts, and not for the Lafettenaufsatzstück. Late production forks, from 1943 and onwards, often don't sport a maker's mark at all. The WaA was repositioned to the left side of the socket, and was the only marking in use.  A marking often encountered, and still not explained. Stbl. 42 EZ. Observed on forks manufactured by dar, and forks with no makers code. Always applied to the top-side of the bottom plate. A very wise man, whose opinions I always listen to, has put forward the theory that the abbreviation Stbl. 42 EZ. is short for Stahlblech 42 Ersatz. An unproved theory, but still the best explanation so far! (Thank you, Vidar Andresen!) Another oddity! The maker Metallindustrie Schönebeck A.G. (S652 / dar) marked their Lafette production with their assigned code S652 inside a triangle until (at least) serial number 1252e / 1941. Then they change to "dar/53" as shown above on both a Aufsatz and a Lafette. On 4030e / 1941 the "53" is gone for good Some Aufsatz with Lager 42 has no maker marking on the right side, the usual WaA on the left side of the socket, but also a second WaA underneath the bottom plate in one out of two variations. The Lager was normally marked with a WaA placed on one of the "squares", matching the WaA-number on the right side of the Aufsatz. This one has been marked with a serial number as well. This was most likely done by a Waffenmeister. Later models also received a maker's code (three letters) on one of the squares. With the introduction of the Lager 42 the manufacturers added "Lager 34" on one of the squares, to avoid confusion. This has been observed on "dar" and "eat" marked Lager 34. The Lager above has a WaA79 to one of the squares on the reverse. "eat" also dated their production in 1943 with "eat 43". The Lager 42 was marked on the machined sides. Those found with makers marking are also marked "Lager 42". The above example was manufactured by Brandenburger Fahrrad und Motorradwerk, Excelsior (S323/fsu) late in 1943, marked PF for the year 1943. The simplified Lager 42 n/A has not been observed with any markings. The bolts used to attach the Lager to the Aufsatz were of industry standard, "M12", but they appear to be purpose-made for the Aufsatz. The bolt heads did not come with markings during the first years of production. On later production Aufsatz the bolts seems to be standard industry bolts, and they come with several different varieties of raised text. But so do postwar bolts..... Towards the end of the war Unteroffizier Josef Greitemeyr of 5. Kompanie Panzergrenadier-Regiment 304 launched an idea in the publication "Von der Front für die Front". He suggested improving the Aufsatz mit Lager 34 by welding on a Lager 42 on the bottom. In order to make this work a cut had to be made in the bottom plate to allow the Lager to rotate.  A slight conceptual confusion here for me. The "Aufsatz mit Lager 34" is here called a "Drehstütze 34".  This example came out of Jugoslavia, and had clearly seen postwar use there, judging from the paint. This example differs from the drawing above, as there is no distance between the two Lagers welded together. Those readers with keen eyesight will notice the marking to the bottom plate, here partially cut away. Those with extremely good eyesight will notice that the Aufsatz in the lower left corner has a weld repair to the metal strip above the hole in the left side-wall.  (Picture courtesy of Folke Myrvang) The combined Lager above is actually an example of the opposite. This is a Lager 42 with a Lager 34 welded on. Not confirming to standards  Not easy to identify, but I assume this is a improvised Lager 42, welded to a standard Lager 34. It has been joined at 90 degrees, so the Lager 34 will no longer serve its original purpose. The standard bolts have been modified into wing-bolts, reason not obvious...  This Aufsatz still has its Lager 34, but appears to have been through a heavy remodeling. An extra support bracket has been welded on to the underside, and the top of the bottom plate has been strengthened with crude welds. The hole for the Stütze has been reduced in size, to fit a smaller pivot. Note that the catch has been removed. It is tempting to assume that the work was done postwar, but the presence of the unaltered Lager 34 suggests that these modifications are WW2 done. A crude piece.....  (Picture courtesy Folke Myrvang) This Aufsatz with Lager 34 has been modified by a Waffenmeister to accept the Пулемёт Дегтярёвa Пехотный, more commonly referred to as the DP-27 Russian LMG (or wrongly, DP-28). (Picture courtesy Folke Myrvang) Yet another Aufsatz with Lager 34 modified. The use for this variation has not been identified yet. And, as with the Stütze, the Waffenmeister would manufacture what his unit couldn't get through the supply system. These Aufsatz' would vary from "almost a perfect copy" to "free fantasy".  The Waffenmeister didn't have access to the same machines as the manufacturer, so he had to improvise. Note the welding seam to the sidewall. The stamped out (down) socket isn't there, but has been replaced with a wider ring that has been welded to the bottom plate. Details are good; he has even included the correct profile on the right arm for maximum elevation with the MG34, even though it has a Lager 42 installed.  Another Waffenmeister made Aufsatz. This craftsman was satisfied with "functional". But he still included the slanting bottom plate! Note that the Lager 34 was made from a solid piece of brass, probably by hand with a file.  (Picture courtesy of Folke Myrvang) Yet another variety, again "functional". This one is rather far from the original, and has probably been made for a fixed gun position. It has no locking catch; instead a hole was used to hold it in position, probably with a pin or a bolt, now long gone. The Lager 34 is handcrafted from one piece of steel, note the "full" arch.  (Clicking on the picture above will open a new picture with the parts' measures) Another "Von der Front für die Front" creation. This one consisted of a complete replica of the Aufsatz and a pivot that could be attached to different objects. The text suggests mounting the pivot on a one meter long wood plank that could be partly buried in the dirt to make it more stable. In a defensive position several pivots could be set up for the same MG, making it easy to change between positions. According to the text, this would turn the LMG into a semi-SMG, good for sustained fire out to 6-800 meters. Postwar production Postwar production of the Aufsatz was, and is, rather limited. First of all, something that never was! This contraption is Portuguese, and was part of the Portuguese AA tripod manufactured for the Madsen LMG. In order to be able to sell them the buyer made MG13 / MG34 adapters and replaced the Madsen-mounts. It has nothing to do with the MG34.  The Jugoslavian M53 Aufsatz. It differs from the WW2 German one in several details. It has two small holes to each side, instead of one large. It has no hole to the bottom plate, which has a deep "V" cut instead. Since it was made exclusively for the M53 the profile cut that allowed for the MG34 at full elevation was dropped. Both arms are identical in shape. Copies for the collector market. Yes, of course. But they are normally easy to tell apart from the real deal if you know how the real deal was made! The biggest challenge is the main piece, which was stamped out in more than one direction.  This Aufsatz is clearly not a WW2 factory manufactured item. It lacks the punched down socket (blue circle) with the welded in tube. And a closer look at the inside revels a welding seam along the inside of the wall (red arrows), where the parts were joined. Couldn't it be a Waffenmeister job? Well, keep in mind that the Waffenmeister didn't score points for the finish, only for a working product. So he would likely not spend hours removing/hiding welds not supposed to be there. Looking at it from underneath we can let all doubt go! The socket has been welded on (since there is no hole on top by the blue circle!), and someone must have spent a copious amount of time smoothening out the welding seam (green arrow). The Lager 34, for some strange reason painted in the same grey as the rest, has a very smooth arch. This was normally cast and machined, leaving a rough surface on the depression. This arch appears to be CNC laser-milled. This copy has a few interesting details. First of all, the metal appears too soft. Note the upper edge which has taken some beating (red arrow). This is not normal for a "weapon grade" accessory. But looking at the bare metal shining through the chipped paint, something is clearly wrong. It is almost silvery (yellow circles), something you would never find on an original piece. The manufacturers code of 2 or 3 letters was never applied letter-for-letter. It was a single stamp, applied in one punch. Here the letters do not line up, clearly a fake stamp. And remember; a Waffenmeister piece will never-ever have a WaA or a maker's code.  |

| Home | For sale | Site map | Contact information | Guest book | Lafette-menu |